Supply Chain Collaboration in the Aerospace Industry

How Data Exchange can support the Aerospace Industry

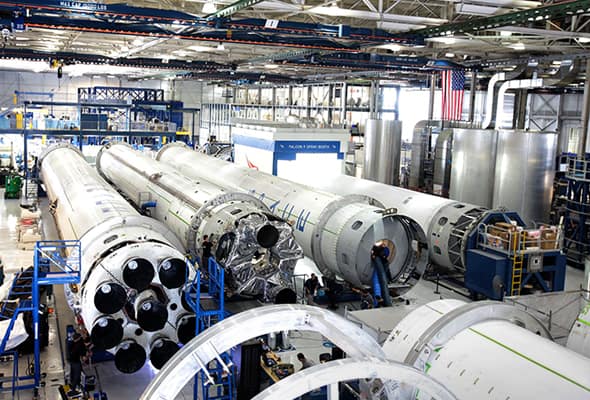

The aerospace industry is one of the world’s most complex and demanding industries. It involves multiple stakeholders and a distributed supply chain worldwide, and acting on aircraft through the whole product lifecycle: From design to manufacturing, and post-delivery in-service support.

In order to achieve operational efficiency, it is crucial for stakeholders to collaborate effectively, but it is essential to consider current challenges.

In this blog post, we will explore these challenges and discuss how data exchange can improve collaboration within the Aerospace industry.

ConnectERPrise connect clients / suppliers, enabling real-time Data Exchange and Digital Continuity.

Information Silos

One of the biggest challenges in the aerospace industry is the presence of information silos:

- Different departments using different software

- Segregated organizations and environments

- Multi-Tiers Suppliers and Sub-Contractors

Software systems and data sources discontinuities lead to fragmented data ecosystem, impacting downstream processes

Data Exchange break down silos and allow different organizations to share data in real-time.

Quality Control & Regulations

The aerospace industry has strict quality control

standards that must be met at every stage of the supply chain.

Compliance to these standards is a “must”to fulfil with

- Regulatory requirements

- Safety directives

- Environmental Conditions

It requires extensive collaboration between suppliers, contractors, and OEMs.

Data exchange improve quality, maintaining adherence between engineering and manufacturing

Complex Distributed Supply Chains

The aerospace industry involves a highly complex and multi-tiered supply chain with numerous suppliers.

Contractors, Sub-contractors, need to coordinate track activities of all parties :

- Consider differences in processes and methods

- Identify bottlenecks or issues

- Anticipate risks of delays

Data exchange increase visibility to track the progress of activities and identify potential bottlenecks.

Conclusion

Collaboration within the aerospace industry is critical for achieving operational efficiency and ensuring compliance with quality and regulatory requirements.

This collaboration is often hindered by challenges such as information silos, multi-level supply chains, quality and regulatory compliance.

Data exchange can help to address these challenges by enabling stakeholders to share data in real-time, providing greater visibility, improving quality control, and ensuring compliance to specification.

With the help of data exchange, stakeholders within the aerospace industry can work together more effectively, resulting in improved productivity, quality, and safety.